At Gifertech we face daily projects where technical demands and tight deadlines make the difference. This case we share is a good example of our ability to offer complete, efficient and customized metal solutions, even in scenarios where every minute counts.

The challenge: a functional part in less than a week

The client, a company in the industrial sector with which we had already collaborated on other occasions, presented us with an urgent need: to develop a tailor-made metal part to be integrated into a critical production line. The starting information was a technical drawing with very specific specifications, and the time available for manufacturing and delivery was less than a week. The demands were high: the part had to have a precise geometry, withstand continuous mechanical stress and conform to very tight tolerances. In addition, it had to be ready to be assembled directly, without the need for additional adjustments.

The process: design, manufacture and control in record time

From the very first moment, we activated an internal protocol that allowed us to speed up deadlines without compromising quality. These were the key phases of the project:

1. Technical validation of the design

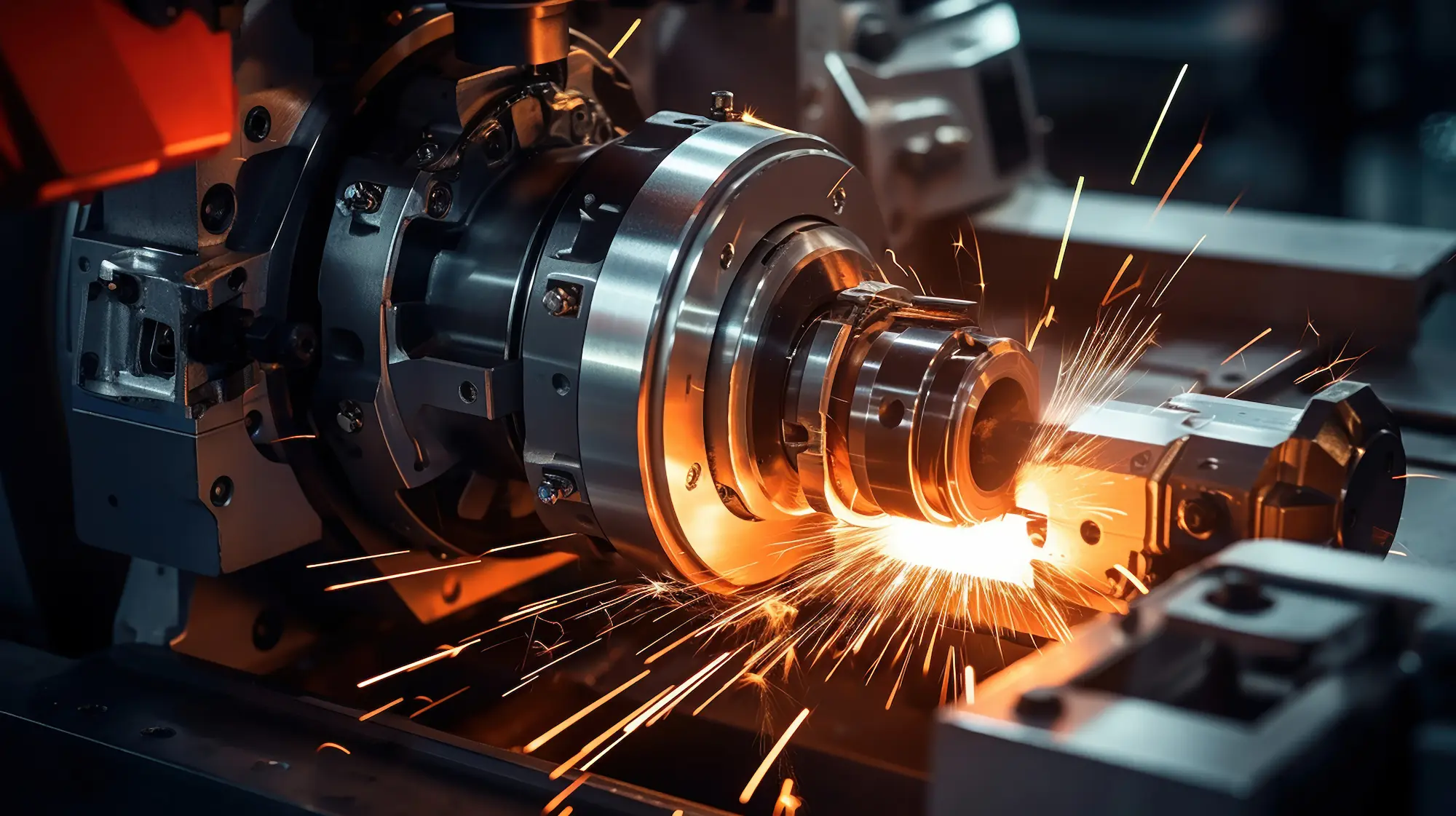

Our technical office team reviewed the client’s initial drawing, evaluating materials, tolerances and conditions of use. From there, the design was optimized to adapt it to our cutting, forming and machining processes. Critical points for dimensional and functional control were also defined. 2. Material selection and process planning. In coordination with our warehouse and suppliers, we selected a steel of adequate technical quality for the required effort. In parallel, the production sequence was organized internally: laser cutting, press forming, CNC machining, welding and final assembly. The entire process was planned to minimize lead times between phases.

3. Fabrication and assembly

During the following days, our specialized operators executed each phase with precision and coordination. The part was laser cut to obtain a clean and precise geometry, then formed and machined to tight tolerances. The parts were welded in our facilities following quality standards, and the complete assembly was assembled for final validation.

4. Quality control and delivery

Prior to delivery, we performed dimensional and functional checks to verify that the part met all customer specifications. We documented the process with internal reports and full traceability. The part was delivered in less than five working days, ready for direct integration into the customer’s line.

The result: a tailor-made solution, with no margin for error

Thanks to the team’s experience, technical planning and the flexibility of our production structure, we were able to meet the customer’s requirements without compromising on quality or deadlines. This type of project clearly shows what we at Gifertech understand by tailor-made metal fabrication: it is not just about producing a part, but about giving a real technical response, complete and adapted to the context. When every hour counts, having a supplier that can design, manufacture, assemble and validate in-house makes all the difference. At Gifertech, that’s our specialty.