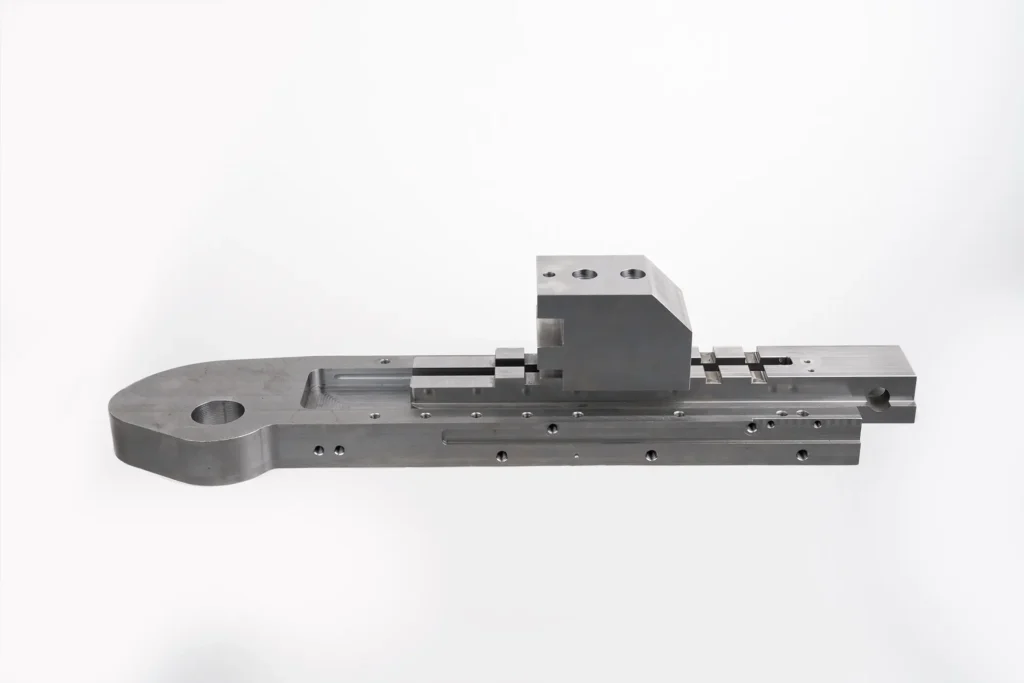

At Gifertech, we are a company specialized in the manufacturing and machining of custom metal parts. Our CNC centers enable us to carry out milling, turning, drilling, and threading operations with high precision. Thanks to the versatility of these machines, we can handle everything from simple parts to complex components.

Using advanced CAD/CAM systems, we can offer customized solutions for industrial projects of any size. Our CNC centers guarantee exceptional precision, both for simple and complex parts, and are ideal for high-volume production work.

CNC centers.

As a machining company for industrial projects, we provide machining services both individually and as part of a larger subset, where other processes and elements are combined to complete each project.

We provide machining services both individually and as part of a larger subset, where other processes and elements are combined to complete each project.

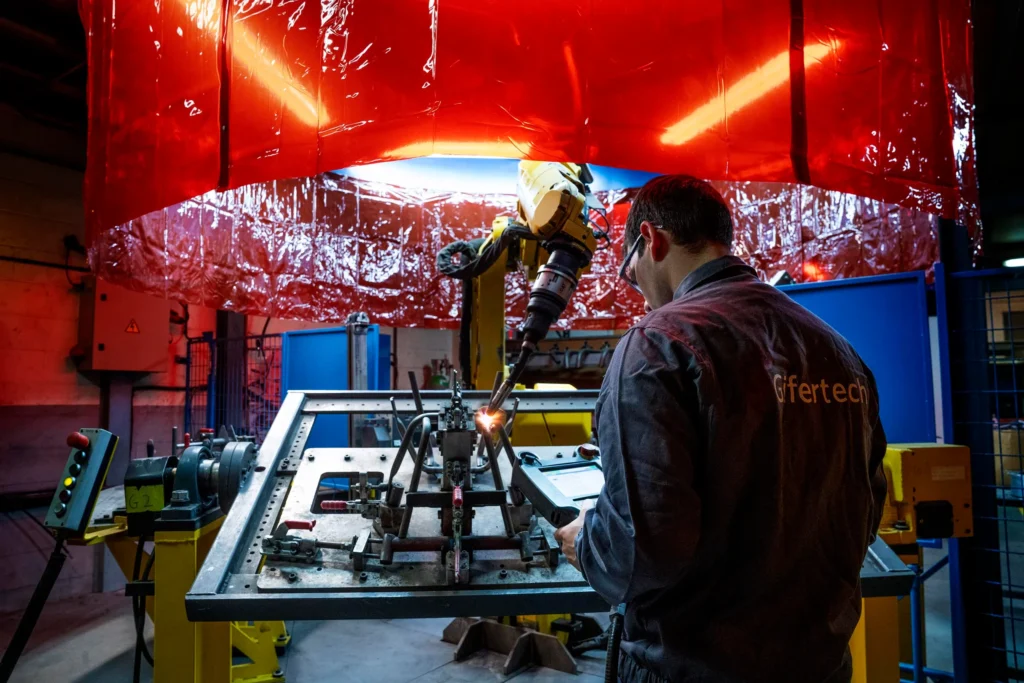

In addition to the machining of metal parts, we have a highly skilled team in precision welding, ensuring that each assembled component is durable and strong. We specialize in offering comprehensive solutions, working efficiently and ensuring quality control at every stage of the process.

Welding.